Descriptive Text of Value Chain Step

Towers are the structural base of the wind turbine that support the rotor and the nacelle module. There are three main types of towers used in large wind turbines: (1) tubular steel towers, (2) lattice towers, and (3) hybrid towers.

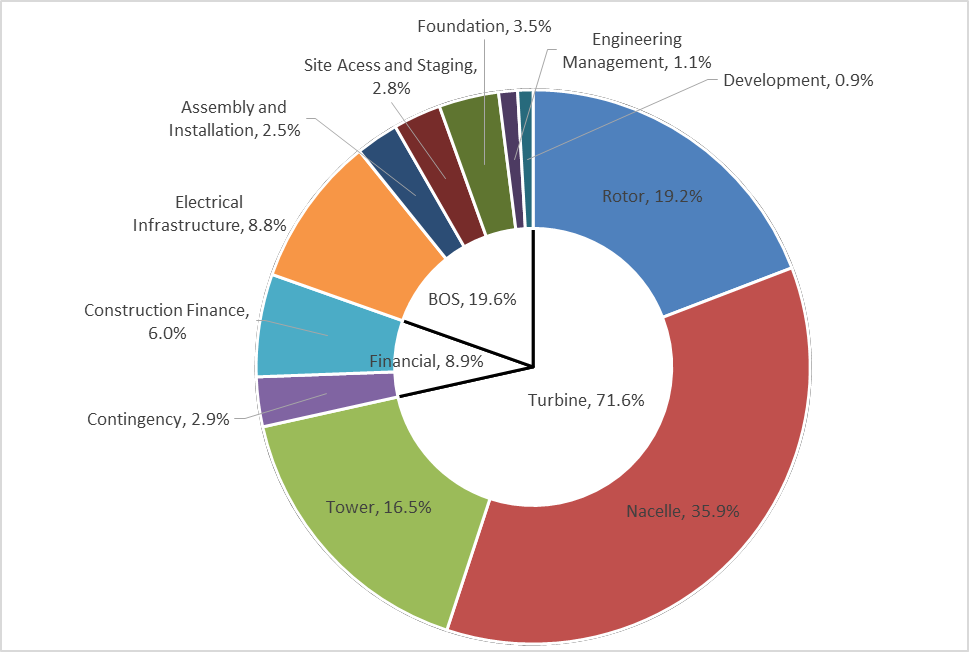

Most modern wind turbine towers are conical tubular steel towers. They are transported in three or four sections and assembled on site. Each section consists of metal rings that are thickest at the bottom and gradually become narrower at the top. During the manufacturing process, steel plate is cut and rolled into the conical shape and then welded into rings. These metal rings are assembled together with vertical joints and then coated with sealants to compose a complete tower section. According to the cost report by National Renewable Energy Laboratory (NREL), the tower module accounted for approximately 16.5% of the cost of an on-shore wind power project in 2015.

To reduce transportation costs, most tower manufacturing facilities are strategically located in close proximity to their customers or to rail lines and deepwater transportation ports for efficient shipping of tower sections. Broadwind Towers, Marmen Energy, Trinity Structural Towers, Ventower and Vestas make up to the vast majority of tower manufacturing capacity in the U.S. As of 2017, there were nine tower manufacturing facilities in operation in the U.S., capable of producing approximately 3,200 towers annually.

Wind tower manufacturing is part of “Turbine and Turbine Generator Set Units Manufacturing” (NAICS 333611). As reported in the 2012 Economic Census, there are 183 establishments and 36,955 employees covered under this industry, with a value of shipments of 16.9 billion dollars. However, even at their most disaggregated level (six-digit code), each of the NAICS code covers a range of components, products, and services beyond those specific to tower manufacturing.

Figure DI.1 Tubular Steel Tower Manufacturing Process

Source: Broadwind Energy, available at: http://www.bwen.com/products/wind-turbine-towers/strategic-manufacturing-locations/default.aspx

Figure DI.2 Capital Expenditures for the Reference Onshore Wind Plant Project

Source: Recreated from Figure 5 in Mone et al. (2017) 2015 Cost of Wind Energy Review, National Renewable Energy Laboratory Technical Report NREL/TP-6A20-66861.