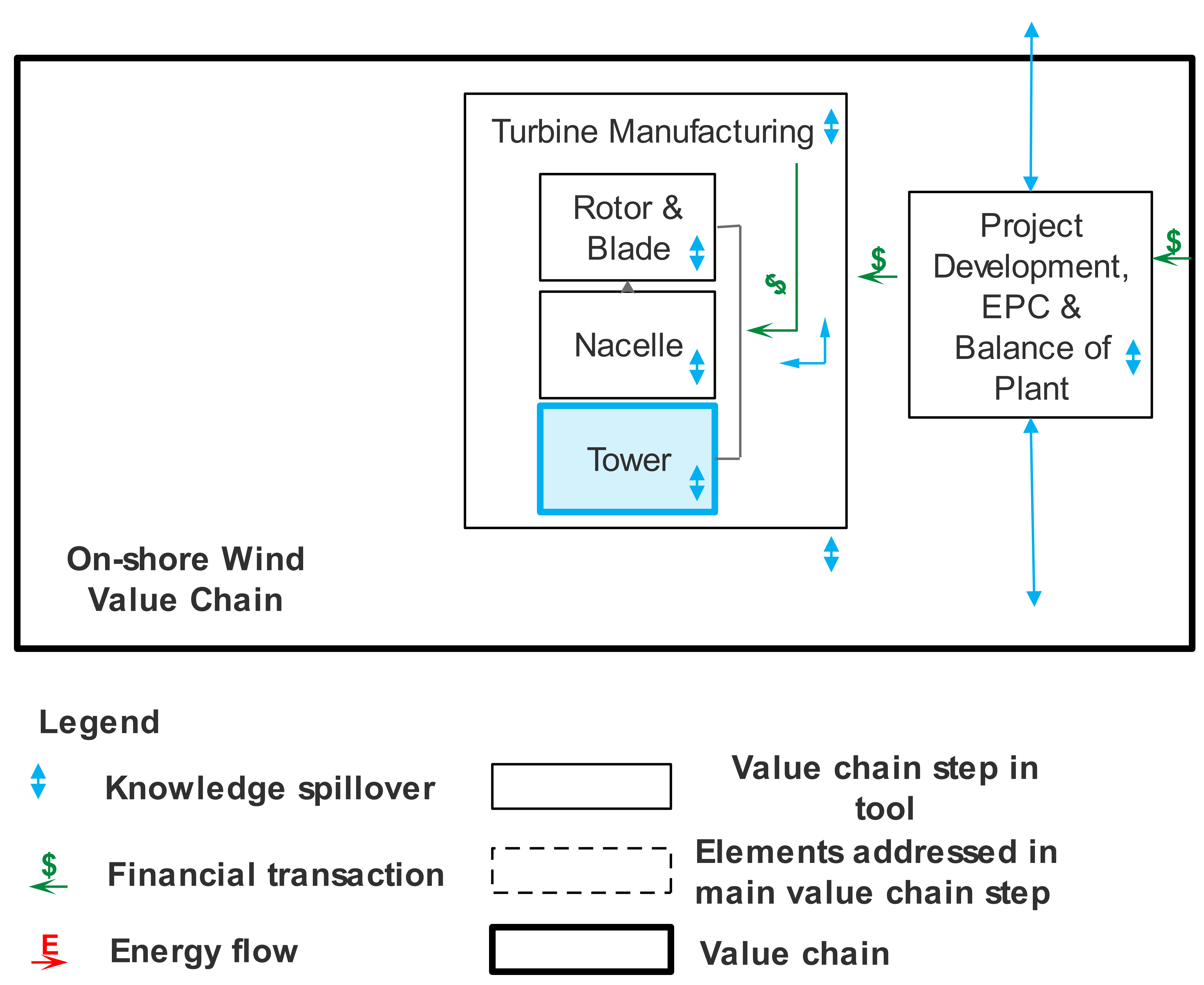

Tower component manufacturing is a key activity encompassed by the Turbine Manufacturing step of our On-Shore Wind value chain. Towers are the structural base of the wind turbine that support the rotor blade and nacelle modules. There are three main types of towers used in large wind turbines: (1) tubular steel towers, (2) lattice towers, and (3) hybrid towers. Most modern wind turbine towers are conical tubular steel towers, which are manufactured in three or four segments and then shipped to the wind project site for final assembly. The tower module accounted for approximately 16.5% of the cost of an on-shore wind power project in 2015. Broadwind Towers, Marmen Energy, Trinity Structural Towers, Ventower and Vestas make up to the vast majority of tower manufacturing capacity in the U.S.. In the current market, the tubular steel tower is the most prominent design because of its high strength-to-weight ratio and comparatively low cost; however, due to the challenge of transporting the large steel components and necessary installation equipment, concrete and hybrid steel-concrete towers are emerging as alternatives.

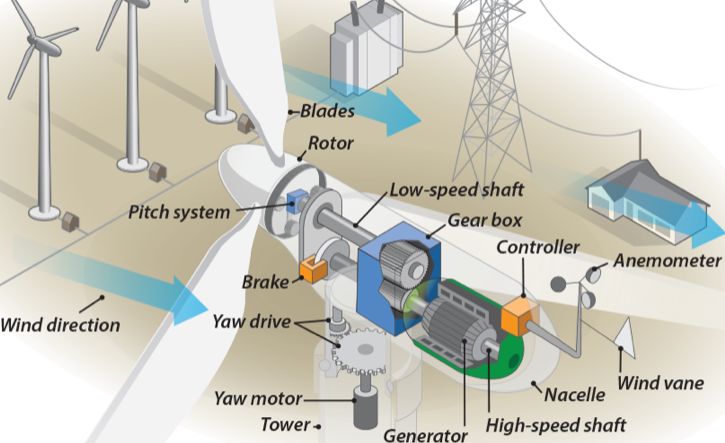

Anatomy of a Wind Turbine

Source: Department of Energy: https://energy.gov/eere/wind/inside-wind-turbine-0

Select an information category (descriptive information, innovative outcomes, strategic conditions, and knowledge conditions) using the tabs to the left or navigate to a different value chain step using the drop-down menu at the top of the page.