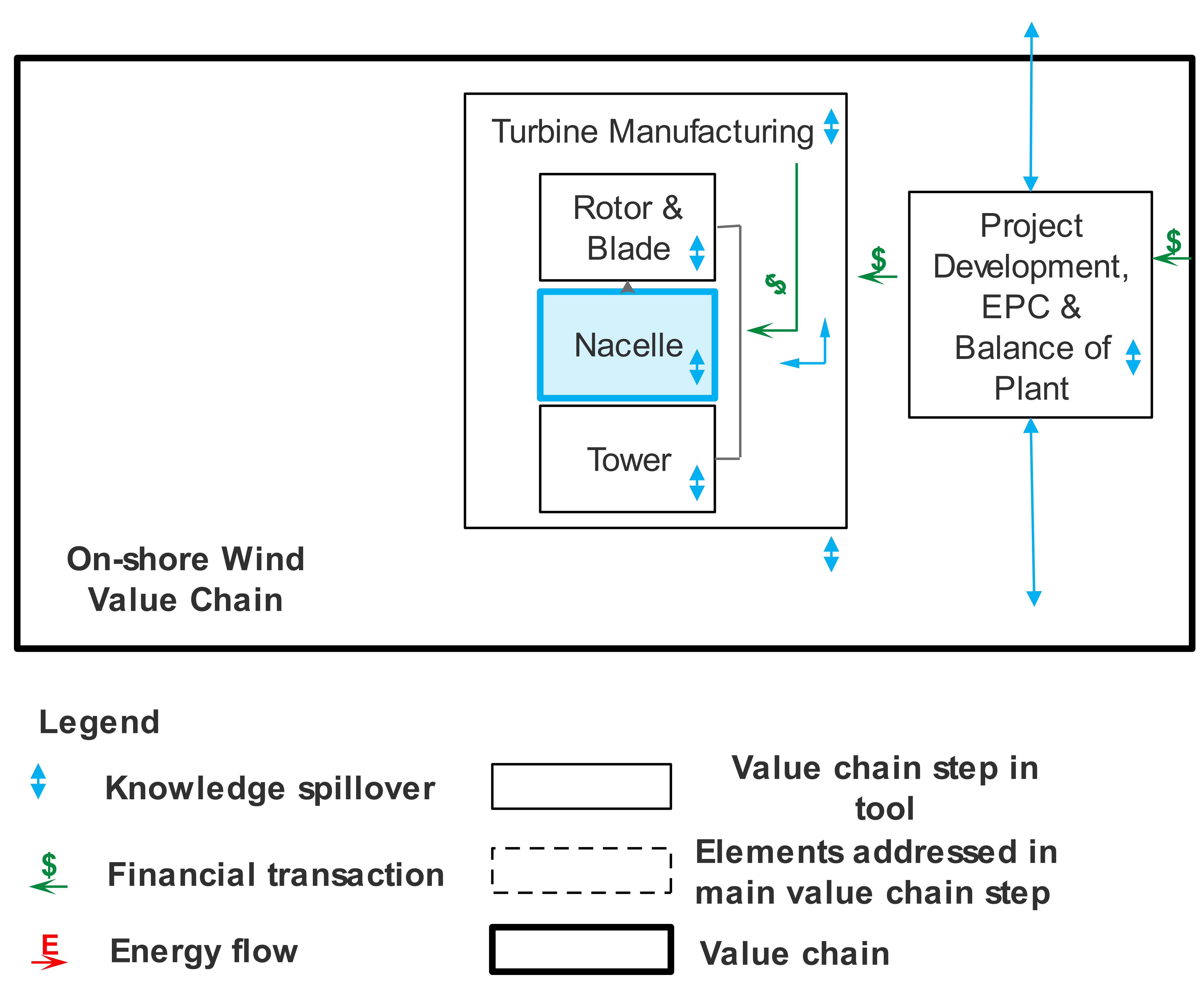

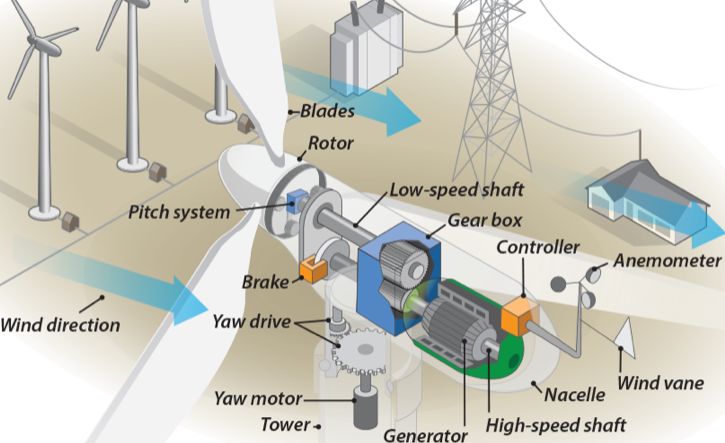

Nacelle manufacturing is a key activity encompassed by the Turbine Manufacturing step of our On-Shore Wind value chain. The nacelle houses the drivetrain, which is typically composed of the rotor shaft, gearbox and generator, and contains a yaw drive system and a control system. There are four primary components of nacelle module production: (1) nacelle structural assembly, (2) drivetrain assembly, (3) nacelle electrical assembly, and (4) yaw assembly. The nacelle module accounted for approximately 36% of the cost of an on-shore wind power project in 2015. As of 2016, GE Renewable Energy, Siemens, Vestas, and Phoenix are the four major wind turbine nacelle assembly manufacturers with production facilities located in the United States. Many recent technological advancements in wind turbine nacelles have focused on improvements to the gearbox and drivetrain systems. The doubly fed induction generator (DFIG) configuration is currently a dominant design in the U.S. wind industry; however, there are recent developments in gearless or direct drive configurations that can improve reliability by eliminating components, such as gearbox bearings, that tend to have higher failure rates.

Anatomy of a Wind Turbine

Source: Department of Energy: https://energy.gov/eere/wind/inside-wind-turbine-0

Select an information category (descriptive information, innovative outcomes, strategic conditions, and knowledge conditions) using the tabs to the left or navigate to a different value chain step using the drop-down menu at the top of the page.