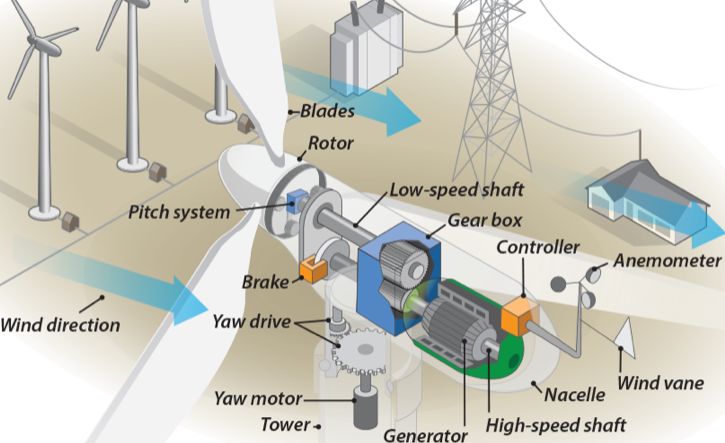

Rotor Blade manufacturing is a key activity encompassed by the Turbine Manufacturing step of our On-Shore Wind value chain. The rotor module includes both the rotor blades and the rotor hub. Rotor blades convert wind energy to low speed rotational energy. The rotor hub, to which the rotor blades are bolted, allows blades to rotate in varying wind speeds. The rotor module accounted for approximately 20% of the cost of an on-shore wind power project in 2015. There are two major types of rotor blade manufacturers in the U.S.: U.S.-owned blade manufacturers with in-house production capabilities, and established European suppliers investing in production in the U.S., rather than shipping internationally manufactured turbine components. The current dominant design turbine blade is composed of layers of fiberglass composite. Recent developments to rotor blades include experimentation with blade material to reduce weight and increase durability, increases in blade length, and advancements in blade assembly through single-piece casting, 3-D printing, and other production process solutions.

Anatomy of a Wind Turbine

Source: Department of Energy: https://energy.gov/eere/wind/inside-wind-turbine-0

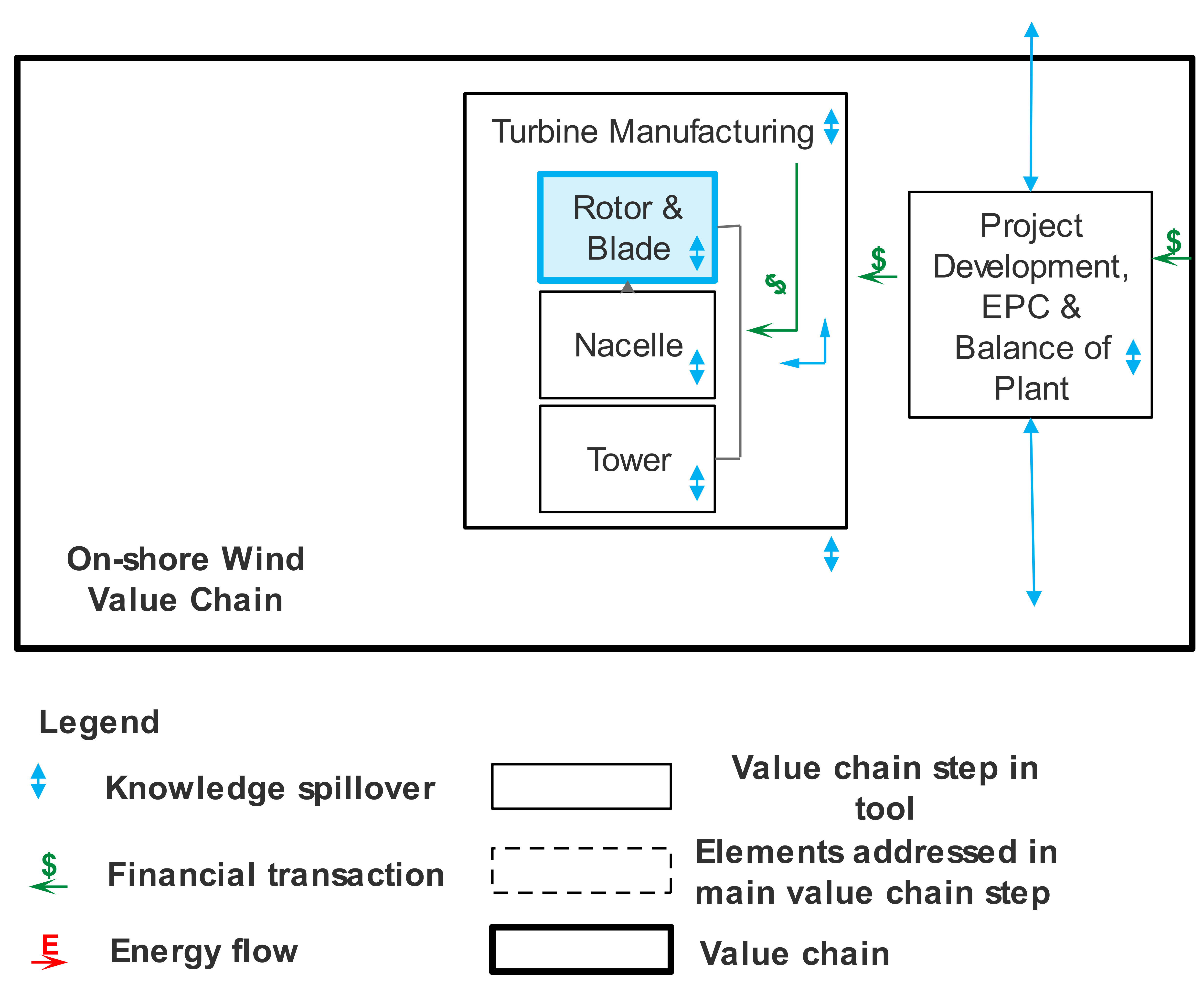

Select an information category (descriptive information, innovative outcomes, strategic conditions, and knowledge conditions) using the tabs to the left or navigate to a different value chain step using the drop-down menu at the top of the page.