As of 2017, on-shore wind produced 1.3% of U.S. electricity generation, and this sector continues to grow rapidly. Building and operating a wind power project is a complex process involving manufacturing, site identification and preparation, permitting, construction, and numerous other sub-tasks.

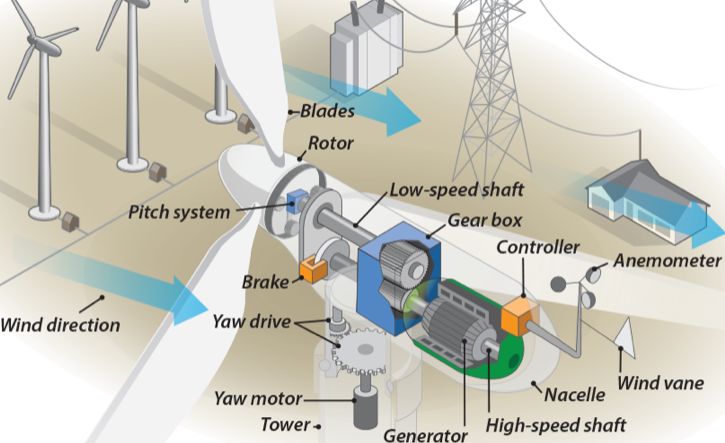

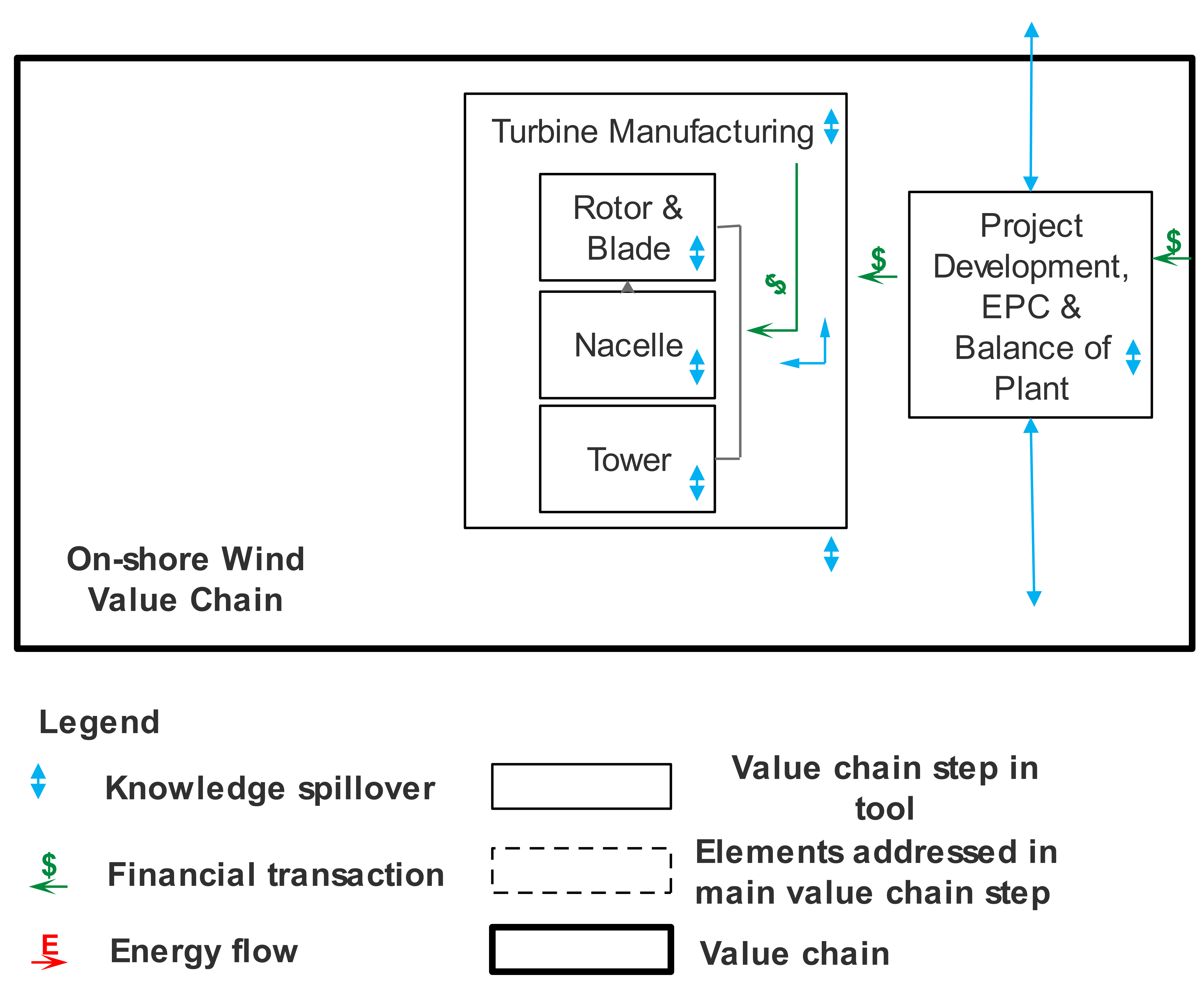

In this value chain, we focus on on-shore (as opposed to off-shore) wind turbine systems. In these systems, wind rotates turbine blades, transferring energy to a generator housed, with other components, inside a nacelle. We divide the on-shore wind value chain into two main steps: 1) Turbine Manufacturing, which includes three sub-steps for critical components: Rotor Blade, Nacelle, and Tower, and 2) Project Development and EPC (Engineering, Procurement, and Construction), in which we discuss the processes involved in siting, permitting, financing, and constructing an on-shore wind facility (including construction of balance of plant infrastructure, such as access roads, foundations, substations, etc.).

Anatomy of a Wind Turbine

Source: Department of Energy: https://energy.gov/eere/wind/inside-wind-turbine-0

In the figure below, we present the simplified value chain used in Energy I-SPARK, which condenses the wind value chain into a manageable number of steps while retaining the detail necessary to investigate key relationships between industry players.

On-shore Wind Value Chain

Note: The dashed boxes in the image above represent key sub-steps in on-shore wind manufacturing which are discussed in more detail separately under the manufacturing steps.

Use the dropdown menu at the top of the page to navigate to the value chain step of interest. After choosing a value chain segment, select a data category to view more detailed information (i.e., descriptive information, innovative outcomes, strategic conditions, knowledge conditions).